HSM Machine

GTF Line

The new GTF Series of Gantry milling machines is characterized by its exceptional robustness. Thanks to a modular construction that combines components selected for weight, rigidity, and cost, the GTF Series is the ideal solution to satisfy even the most demanding customers.Learn more

Linea M

The LINEA M is designed to perform complex machining typical of precision molds and equipment, offering a highly effective solution for semi-finishing and finishing operations.Learn more

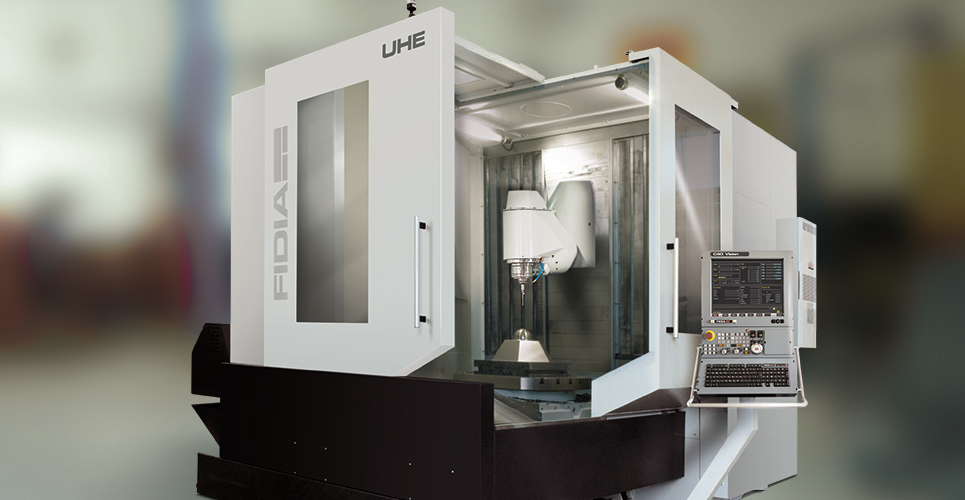

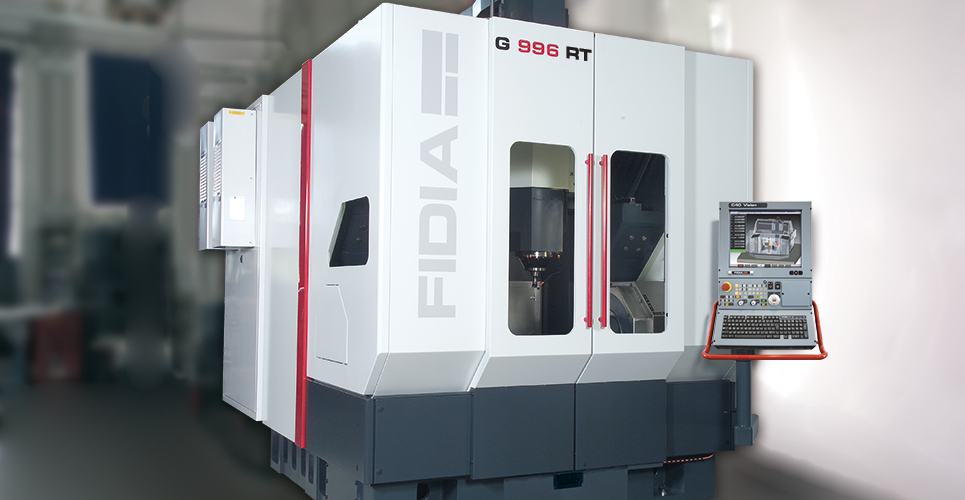

BRIDGE

Fidia’s BRIDGE is a 5-axis machine featuring a fixed portal structure and a moving table. This solution combines exceptional robustness with excellent precision.Learn more

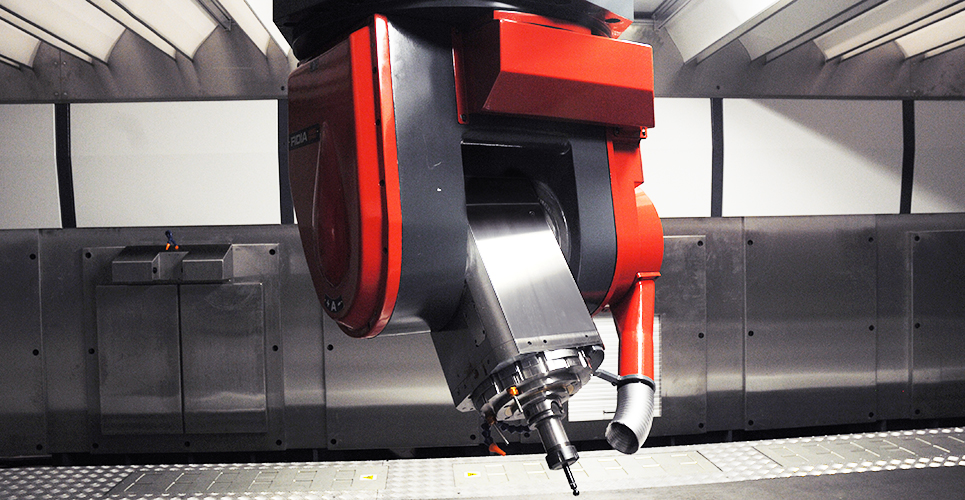

GTF Line

The GTF Series of Gantry milling machines is characterized by its exceptional robustness. Thanks to a modular construction that combines components selected for weight, rigidity, and cost, the GTF Series is the ideal solution to satisfy even the most demanding customers.

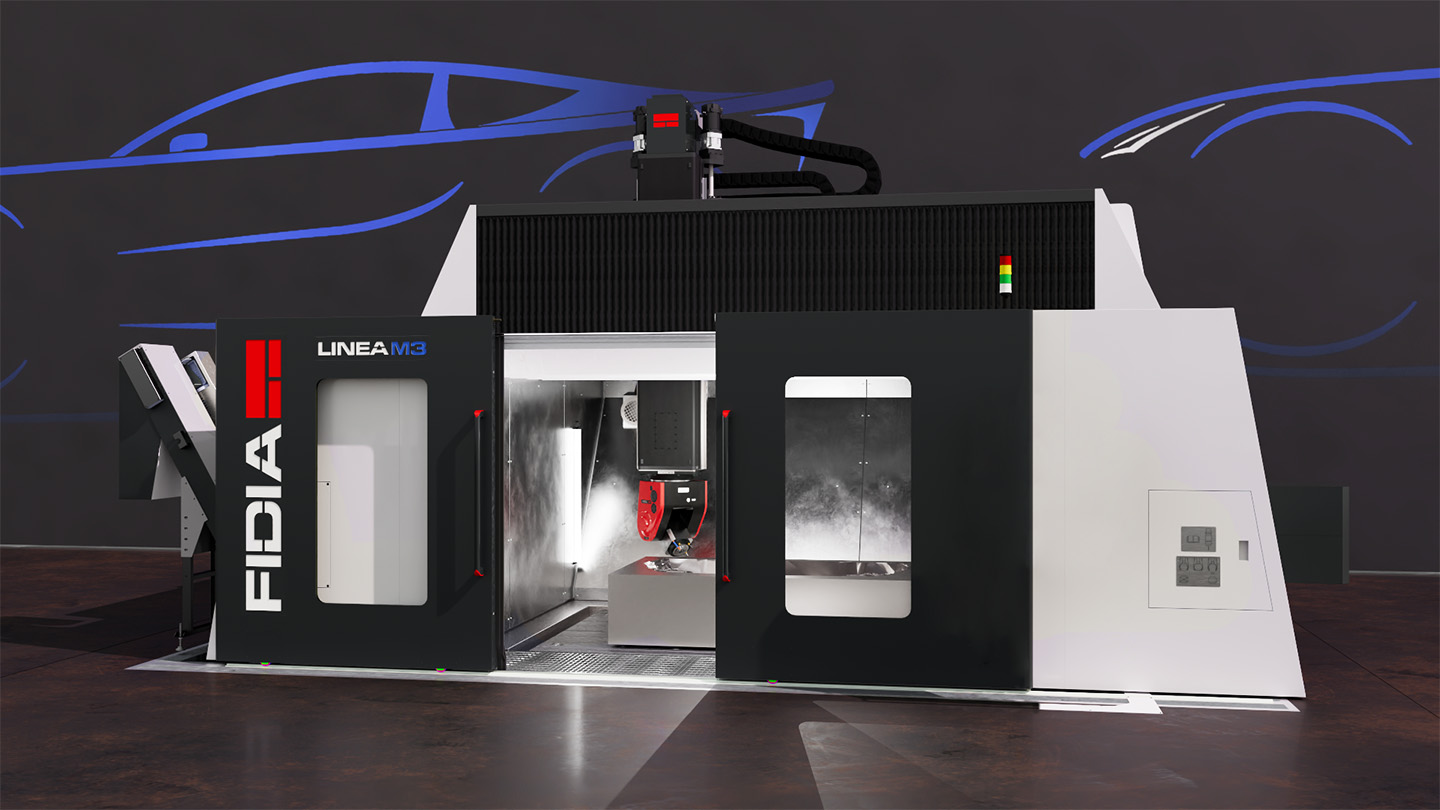

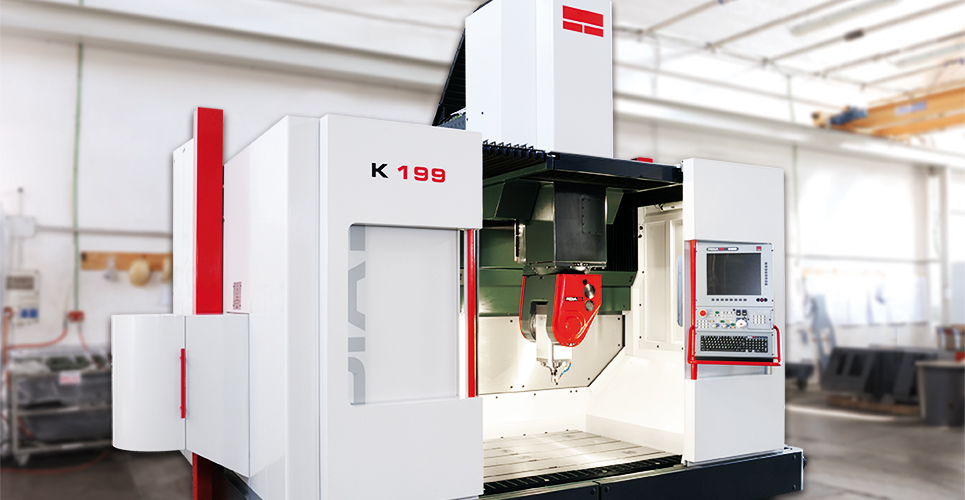

Linea M

The LINEA M is designed to perform complex machining typical of precision molds and equipment, offering a highly effective solution for semi-finishing and finishing operations.

Learn more

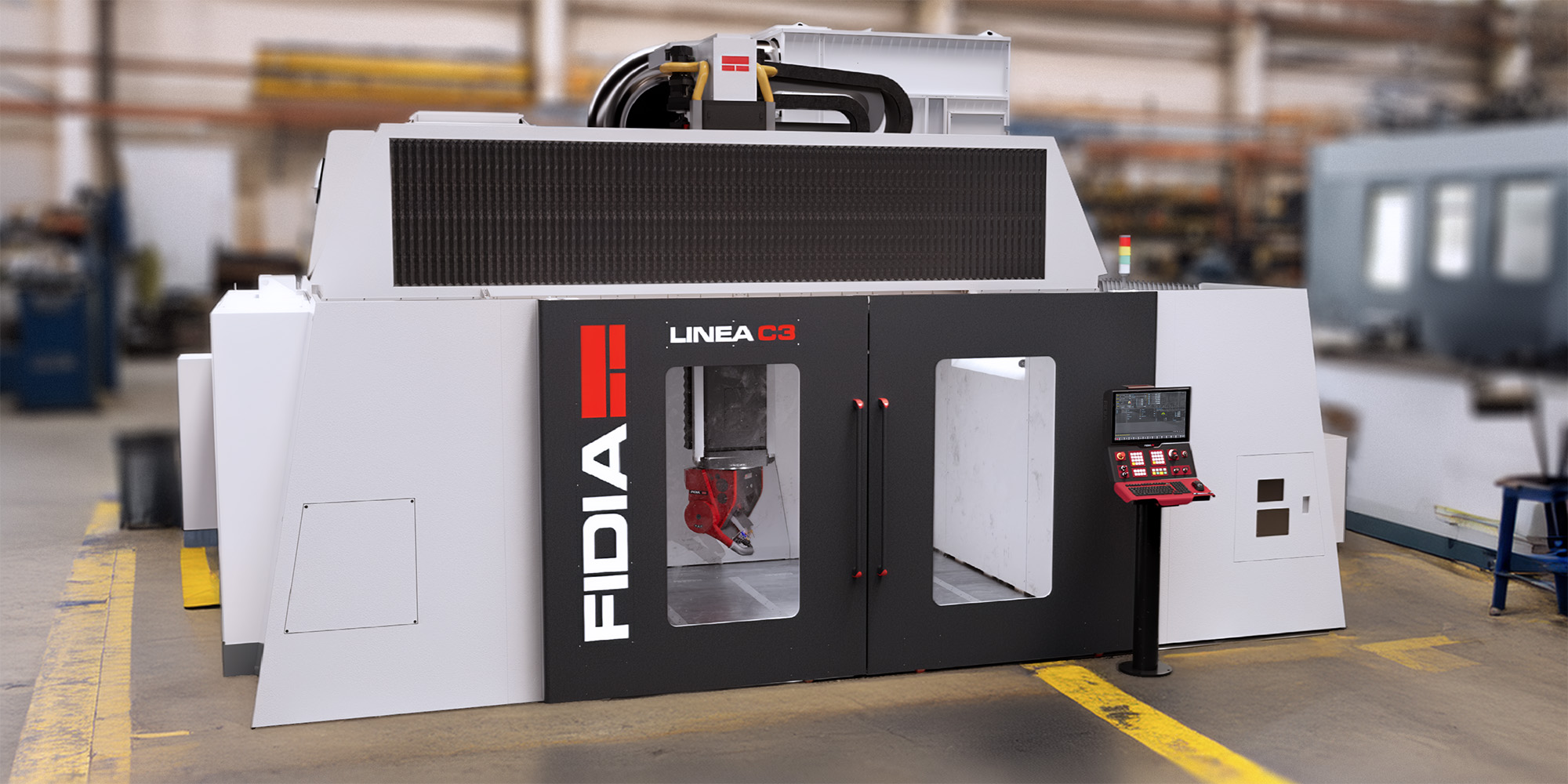

Linea M: General descriptionBridge

Fidia’s BRIDGE is a 5-axis machine featuring a fixed portal structure and a moving table. This solution combines exceptional robustness with excellent precision.

Learn more

Bridge: General descriptionNumerical Controls

C20

Featuring a linear and compact design, the C20 numerical control is ideal for 3- and 5- axis high range milling machines.Discover more

nC19

Designed to be extremely compact and versatile, it adopts a physical keyboard and a newly designed button panel which increase usability and ergonomics. With the 18.5" wide multi-touch and full HD screen, everything is kept under control and supervised.Discover more

C20

Featuring a linear and compact design, the C20 numerical control is ideal for 3- and 5- axis high range milling machines.

Discover more

C20: High performancenC19

Designed to be extremely compact and versatile, it adopts a physical keyboard and a newly designed button panel which increase usability and ergonomics. With the 18.5" wide multi-touch and full HD screen, everything is kept under control and supervised.

Discover more

nC19: Compact and functional

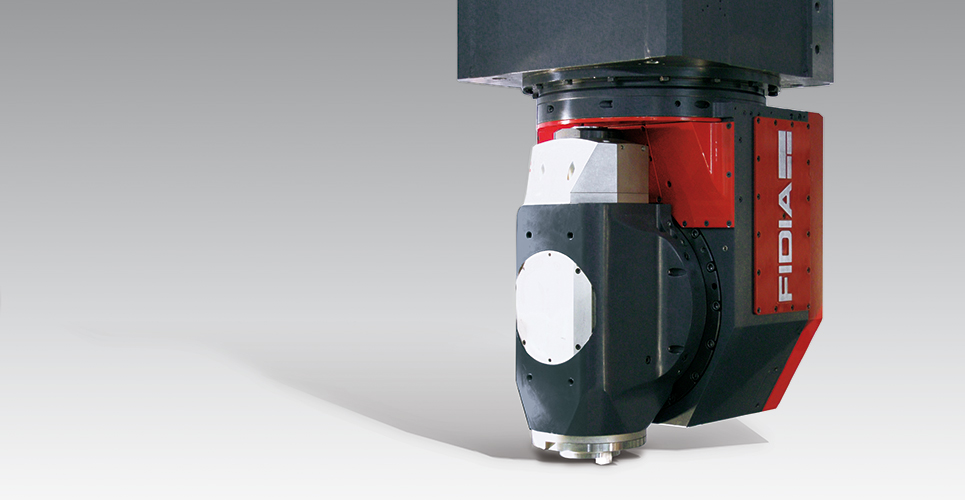

Milling heads

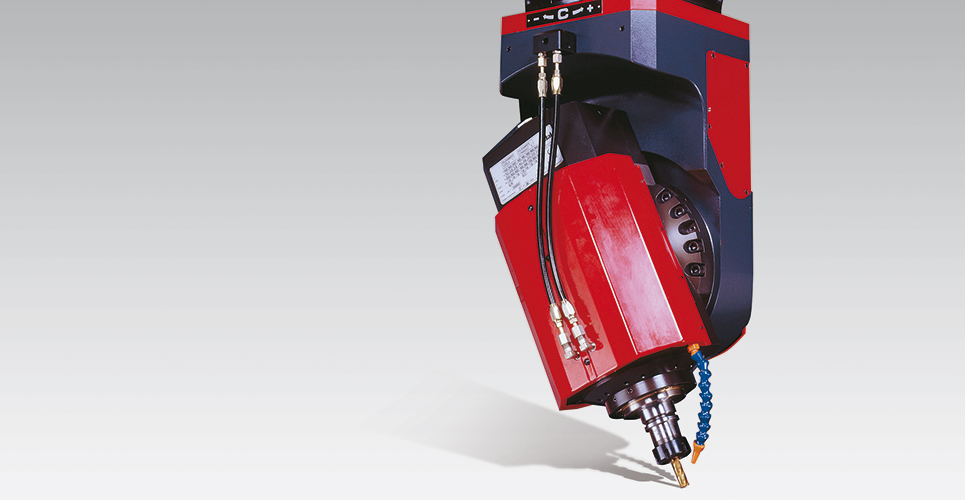

M5D

M5D offers an extraordinary volume of chip removal on aluminum, providing an unprecedented efficiency to the manufacturing of large aircraft structural parts.Discover more

M5E

M5E head offers roughing capacity together with high speed on cast iron, steel and tough materials.M5H

M5H head with mechanical spindle unit develops high torque and integrates automatic accessories change to allow for access into narrow spaces.M5S

The M5S features a cast iron body and symmetrical fork structure providing optimal thermal stability.M5A

M5A is a continuous bi-rotary head ideal to perform the complete machining cycle, from roughing to finishing.M5C

Made in aluminium alloy, M5C is the "light" version of M5A.M5B

The M5B/22 indexed bi-rotary head has been designed to provide medium-sized machines with a spindle that can be oriented and which has high stock removal capacity and high rpm.Discover more

M5D

M5D offers an extraordinary volume of chip removal on aluminum, providing an unprecedented efficiency to the manufacturing of large aircraft structural parts.

Discover more

M5D: Continuous bi-rotary head, spindle power 100 KWM5E

M5E head offers roughing capacity together with high speed on cast iron, steel and tough materials.

M5H

M5H head with mechanical spindle unit develops high torque and integrates automatic accessories change to allow for access into narrow spaces.

M5S

The M5S features a cast iron body and symmetrical fork structure providing optimal thermal stability.

M5A

M5A is a continuous bi-rotary head ideal to perform the complete machining cycle, from roughing to finishing.

M5C

Made in aluminium alloy, M5C is the "light" version of M5A.

M5B

The M5B/22 indexed bi-rotary head has been designed to provide medium-sized machines with a spindle that can be oriented and which has high stock removal capacity and high rpm.

Discover more

M5B/22: Indexed bi-rotary head, spindle power 22 KW

Accessories

HMS

HMS is a device for measuring and compensating geometric error on continuous or indexed bi-rotary heads and roto-tilting tables. It improves the accuracy and quality of 5-axis machining without requiring complex intervention from specialist technicians.Discover more

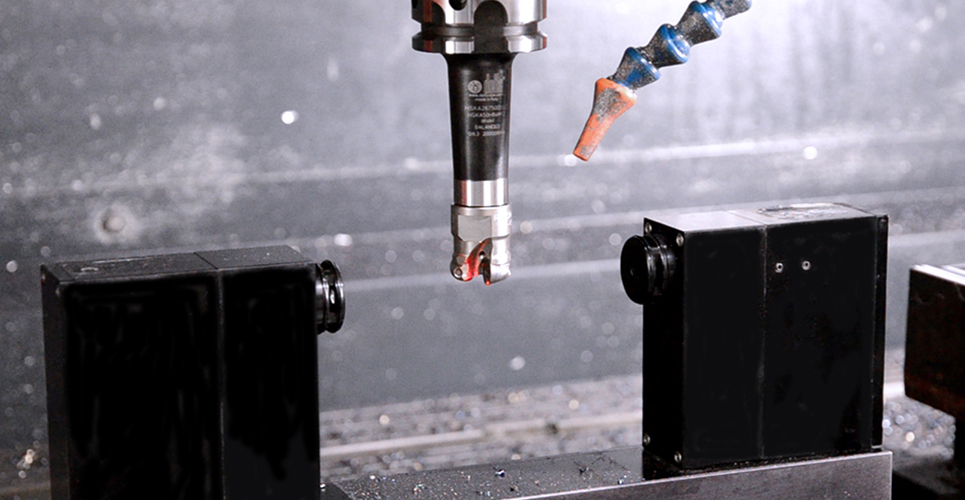

TMSC

TMSC device is based on a focused laser beam mounted on a specific structure to placed on the machine and can be used to measure length, diametre of the tool and check the shape. The measurements are made with the spindle in rotation. There are measuring cycles for ten types of tools, which include the principal shapes of tools used for milling.Discover more

Pushbutton panels

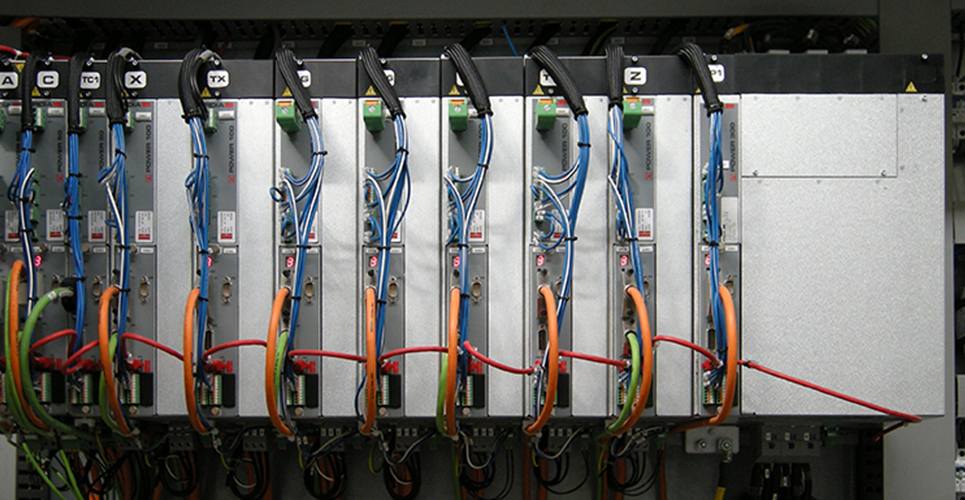

The Fidia handheld pushbutton panels replicate the most frequently used commands on the main pushbutton panel. Especially useful on large machines, they enable the machine to be commanded from a more convenient position and allow for a closer control of machining.Digital drives (XPower series)

Fidia Digital drives (XPower series) have been designed for axis and spindle movement. Ideal for mounting on a wide range of machine tools, they can command brushless, linear or torque axis motors and synchronous and asynchronous spindles.Discover more

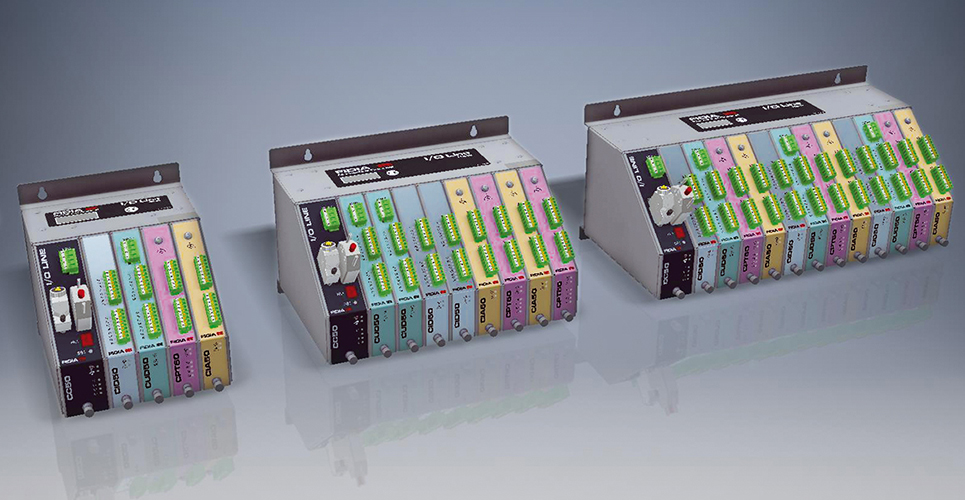

I/O Modules

The I/O Line™ is the latest generation of input/output Fidia modules; designed to be installed inside the machine tool electrical cabinet they are connected to the numerical control through the Fidia FFB bus.Discover more

HMS

HMS is a device for measuring and compensating geometric error on continuous or indexed bi-rotary heads and roto-tilting tables.

It improves the accuracy and quality of 5-axis machining without requiring complex intervention from specialist technicians.

Discover more

HMS: For compensating geometric errorTMSC

TMSC device is based on a focused laser beam mounted on a specific structure to placed on the machine and can be used to measure length, diametre of the tool and check the shape. The measurements are made with the spindle in rotation. There are measuring cycles for ten types of tools, which include the principal shapes of tools used for milling.

Discover more

TMSC: Tool measurement devicePushbutton panels

The Fidia handheld pushbutton panels replicate the most frequently used commands on the main pushbutton panel. Especially useful on large machines, they enable the machine to be commanded from a more convenient position and allow for a closer control of machining.

Digital drives (XPower series)

Fidia Digital drives (Xpower series) have been designed for axis and spindle movement. Ideal for mounting on a wide range of machine tools, they can command brushless, linear or torque axis motors and synchronous and asynchronous spindles.

Discover more

Digital drives (XPower series)I/O Modules

The new Fidia I/O Modules™ is the latest generation of input/output; designed to be installed inside the machine tool electrical cabinet they are connected to the numerical control through the Fidia FFB bus.

Discover more

I/O Modules

Software

ViMill

ViMill is an anti-collision system that operates on the machine. Being fully integrated into the Fidia numerical control, ViMill is constantly active during all phases of machine tool operation both when working from a program and when positioning the axes using the pushbutton panel or the handwheel.Discover more

Machine Monitor

The Machine Monitor is a software component designed to run on the FIDIA CNC background with no user interface. Its purpose is to monitor NC variables and parameters.Discover more

Velocity 6

Fidia introduces Velocity 6™, a new technique for axes control, that significantly improves the performances of the machine, in 3 axes as well as in 5 axes machining.Discover more

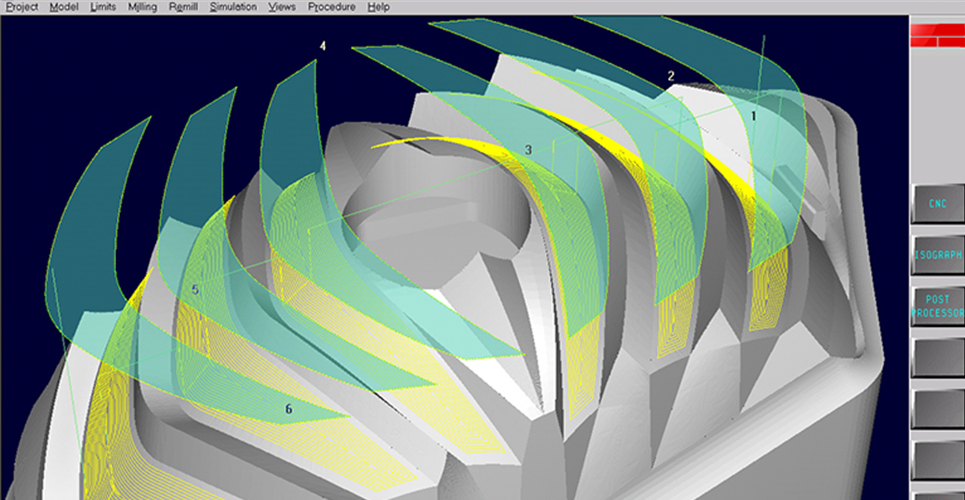

HiMill

HiMill® is the Fidia CAM software for the machining of dies, models and aeronautical components. The software allows for reading of VDA-FS, IGES, STL, CATIA formats and digitized surfaces. It generates tool paths, from roughing out to superfinishing, with a wide range of machining strategies.Discover more

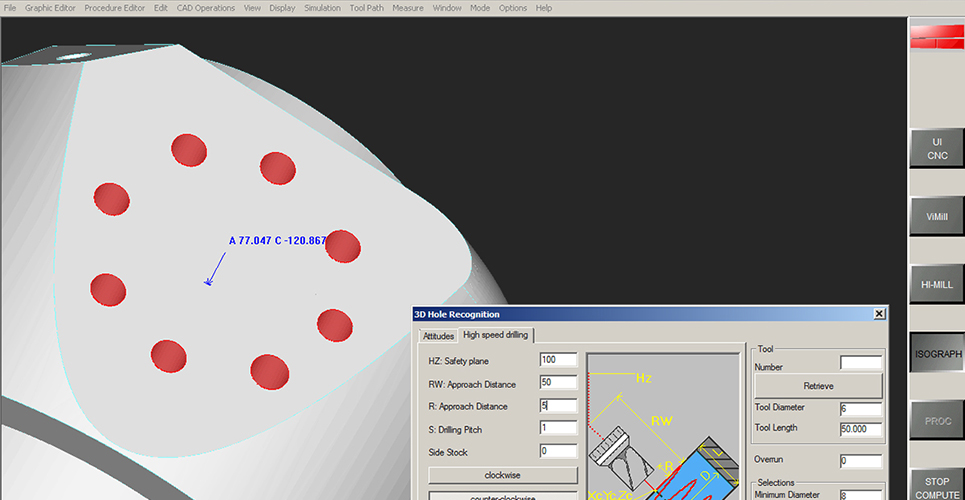

Isograph

With the innovative user interface, profiles can be defined by simply using the softkeys and mouse. Interaction is, therefore, easy and immediate even for operators with no specific programming knowledge. A wide range of fixed drilling cycles and complex cycles for the pocket milling of any profile complete the package.Discover more

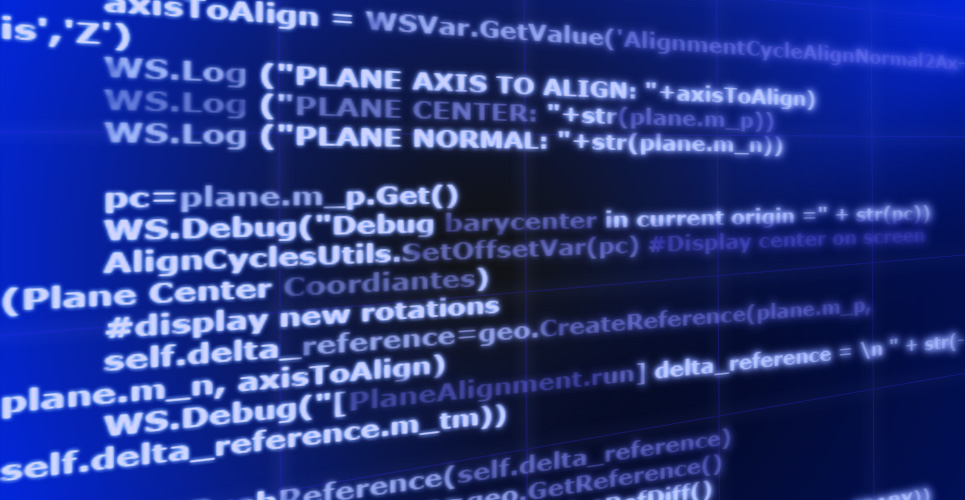

PRC-PRX

The Fidia CNC provides for a sequence of operations that can be stored in a “Procedure” (PRC) and then executed automatically. This technique simplifies repetitive machining operations, improves operating safety and enables a series of unmanned machining operations to be performed. For more demanding automation needs, the PRX advanced programming language is available, extending the application of “Procedures” to the most complex cases.Discover more

ViMill

ViMill is an anti-collision system that operates on the machine. Being fully integrated into the Fidia numerical control, ViMill is constantly active during all phases of machine tool operation both when working from a program and when positioning the axes using the pushbutton panel or the handwheel.

Discover more

ViMill: Anti-collision systemMachine Monitor

The Machine Monitor is a software component designed to run on the FIDIA CNC background with no user interface. Its purpose is to monitor NC variables and parameters.

Discover more

Machine Monitor: Monitoring systemVelocity 6

Fidia introduces Velocity 6™, a new technique for axes control, that significantly improves the performances of the machine, in 3 axes as well as in 5 axes machining.

Discover more

Velocity 6™: Quality & high speedHiMill

HiMill® is the Fidia CAM software for the machining of dies, models and aeronautical components. The software allows for reading of VDA-FS, IGES, STL, CATIA formats and digitized surfaces. It generates tool paths, from roughing out to superfinishing, with a wide range of machining strategies.

Discover more

HiMill: The 3D CAM easy and intuitiveIsograph

With the innovative user interface, profiles can be defined by simply using the softkeys and mouse. Interaction is, therefore, easy and immediate even for operators with no specific programming knowledge. A wide range of fixed drilling cycles and complex cycles for the pocket milling of any profile complete the package.

Discover more

Isograph: The 2D ½ CAD/CAM for on bord programmingPRC-PRX

The Fidia CNC provides for a sequence of operations that can be stored in a “Procedure” (PRC) and then executed automatically. This technique simplifies repetitive machining operations, improves operating safety and enables a series of unmanned machining operations to be performed.

For more demanding automation needs, the PRX advanced programming language is available, extending the application of “Procedures” to the most complex cases.