K211 K214 - K411 K414

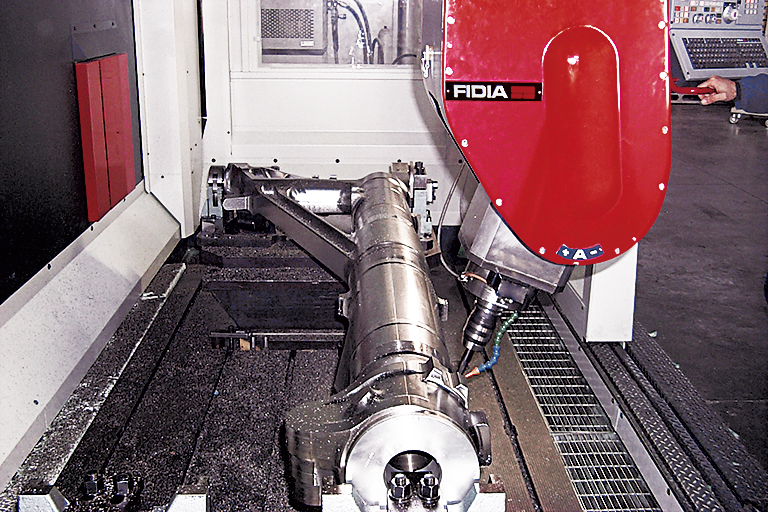

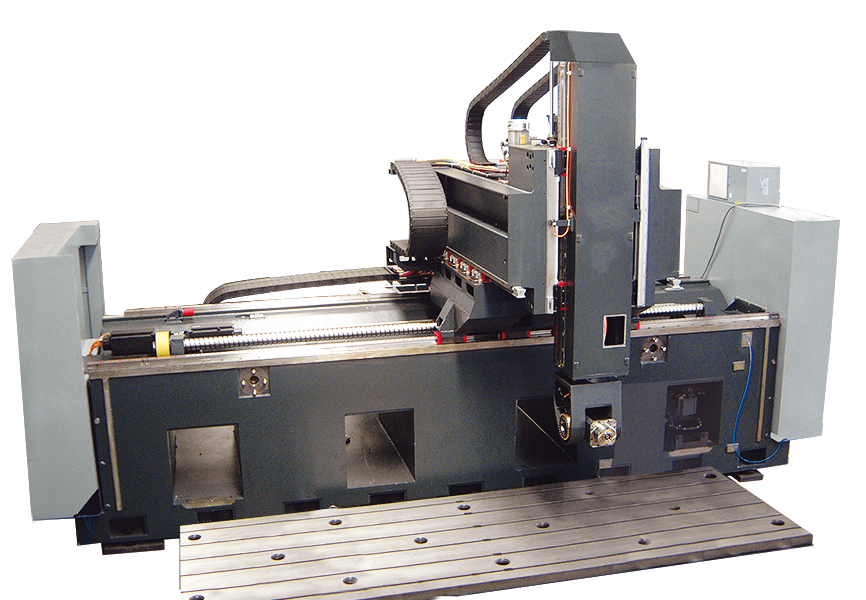

This range of K Series machines is available in various X axis lengths, taking advantage of the modular design of the fixed bed. The adoption of a rack and pinion system with a dual motor for compensation of backlash ensures excellent X axis dynamics over any length.

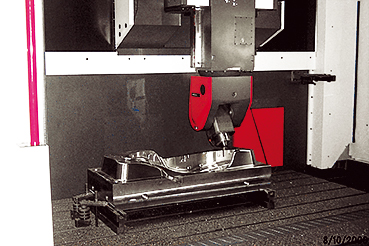

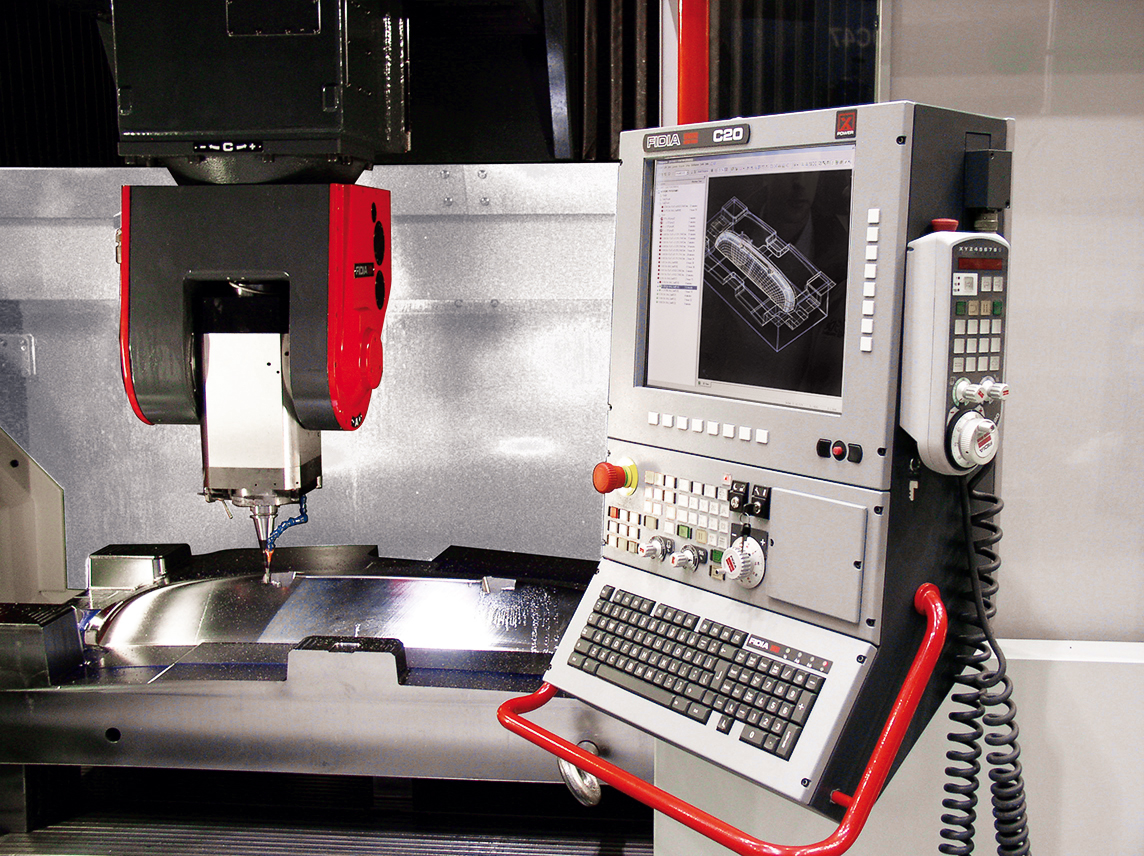

The K Series is the ideal partner when machining light alloy structural components, such as the long, narrow parts typically required for the aerospace industry.

Brochure K Series

General catalog KDGH

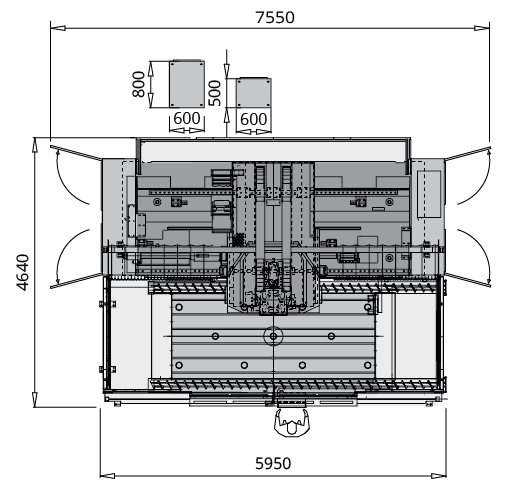

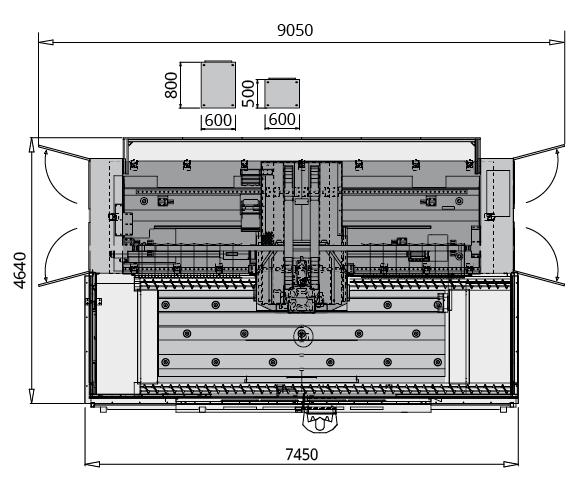

Layout and technical specifications

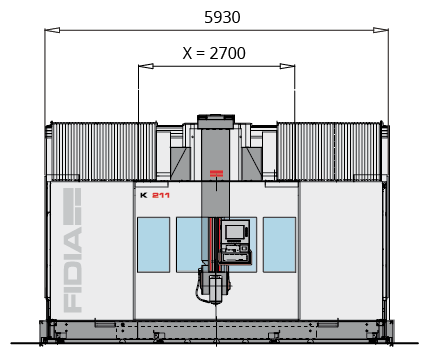

K211 K214

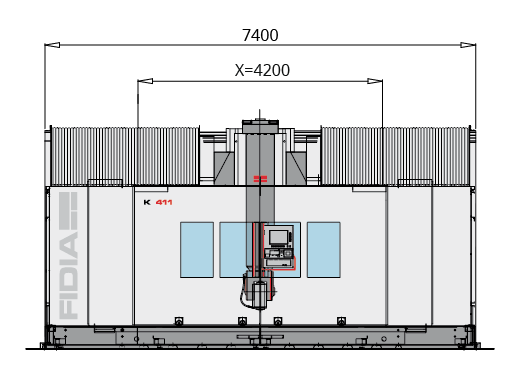

K411 K414

| K211/214 | K411/414 | ||

| Linear axes travel | |||

| X(*) | 2700 mm | 4200 mm | |

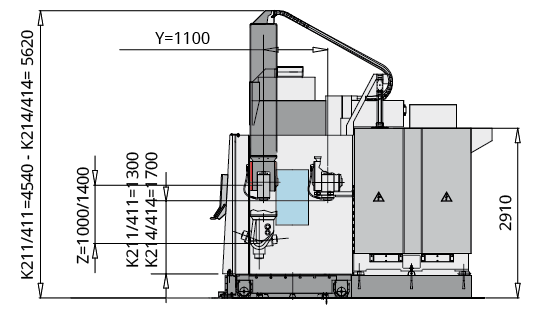

| Y(*) | 1100 mm | ||

| Z | 1000/1400 mm | ||

| Axes speed | X | Y | Z |

| 50 m/min (1968 ipm) | 40 m/min (1575 ipm) | 30 m/min (1181 ipm) | |

| Positioning accuracy | |||

| X Y Z | ± 0,006 ± 0,005 ± 0,004 mm | ± 0,0075 ± 0,005 ± 0,004 mm | |

| Work-piece table: | |||

| Dimensions | 3500 x 1500 mm | 5000 x 1500 mm | |

| T-Slots | n° 6 - pitch 250 mm (10”) | ||

| Loading capacity | 22000 kg | 32000 kg | |

| Tool magazine | |||

| No of positions | 42 - 84 | ||

| Weight | |||

| 26000 kg (57319 lbs) | 32000 kg 32000 kg (70547 lbs) | ||

(*) +150 mm rotating the C axis with vertical spindle