LINEA C

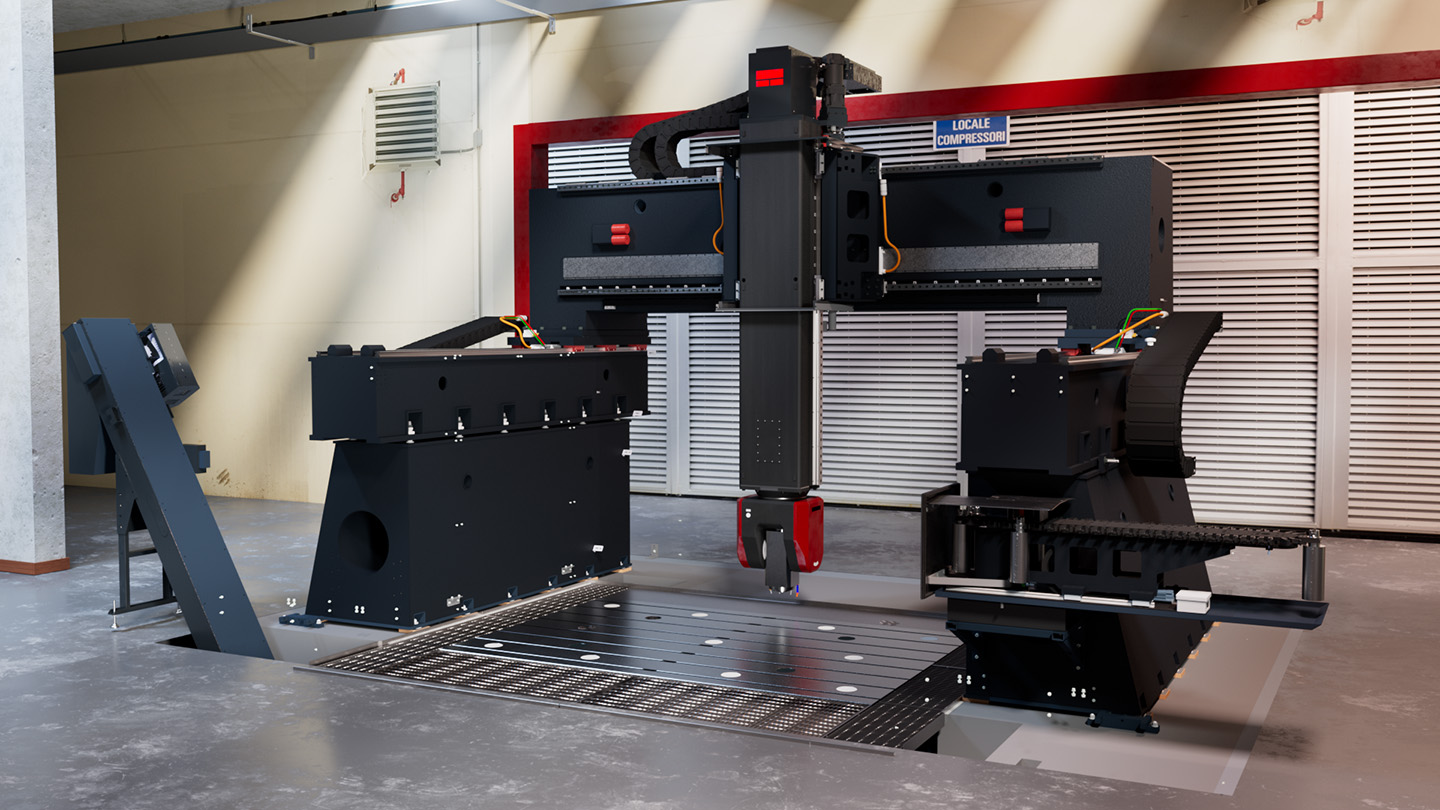

The Gantry for Composites

LINEA C was created to meet the growing demand for precision in the field of machining composite materials, such as CFRP, multi-layer composites, honeycomb, and CMC (Ceramic Matrix Composites).

The structural robustness, equal to that of aluminum and steel milling machines, ensures stable positioning and contouring precision with 5 continuous axes. Linear motors guarantee maximum speed and acceleration.

The heads are equipped with spindles and dust extraction systems specifically designed for machining the hardest and most abrasive materials. In the operating area, various configurations can be combined with the clamping equipment typically used for composite materials.

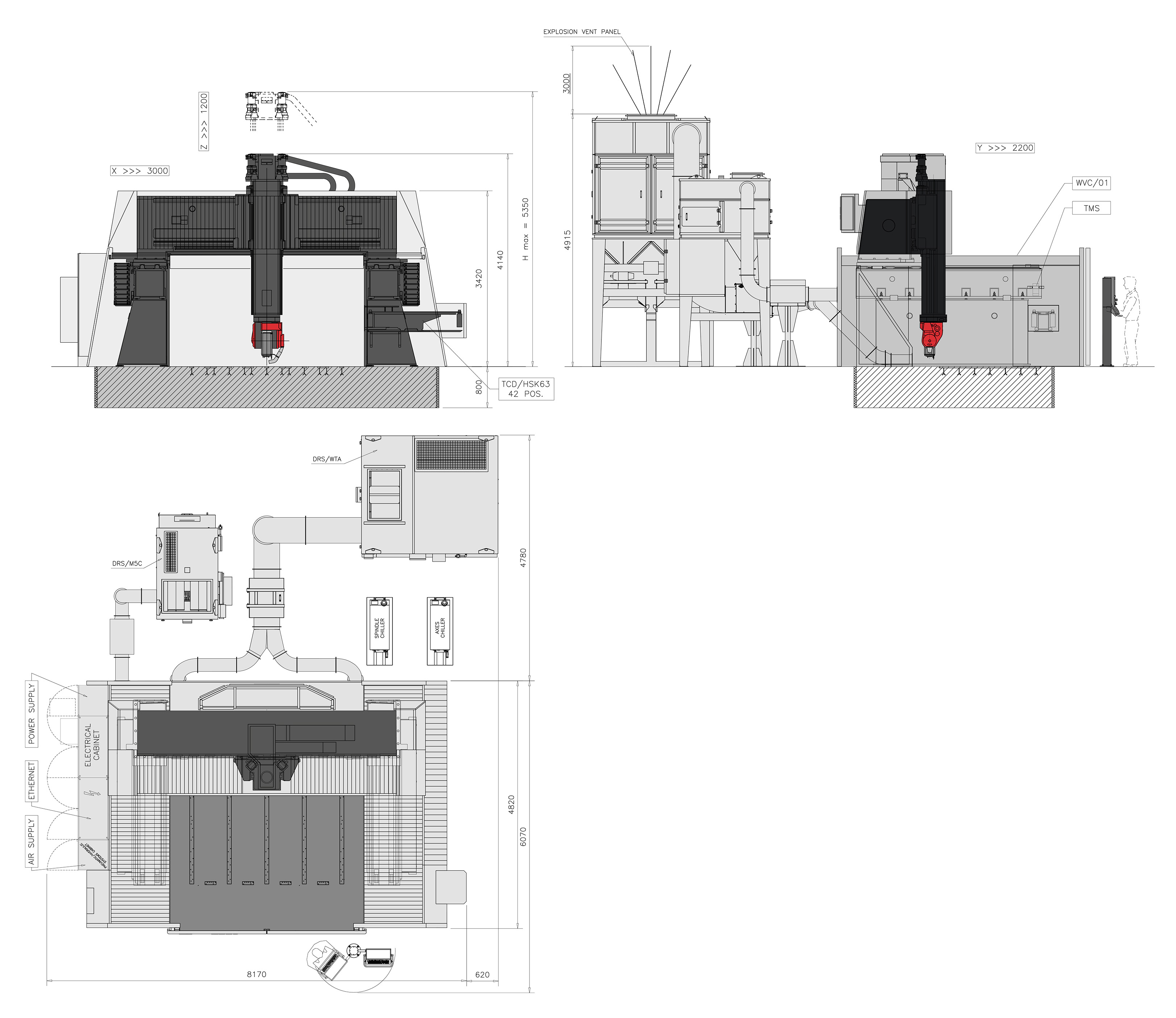

Specifiche tecniche e Layout

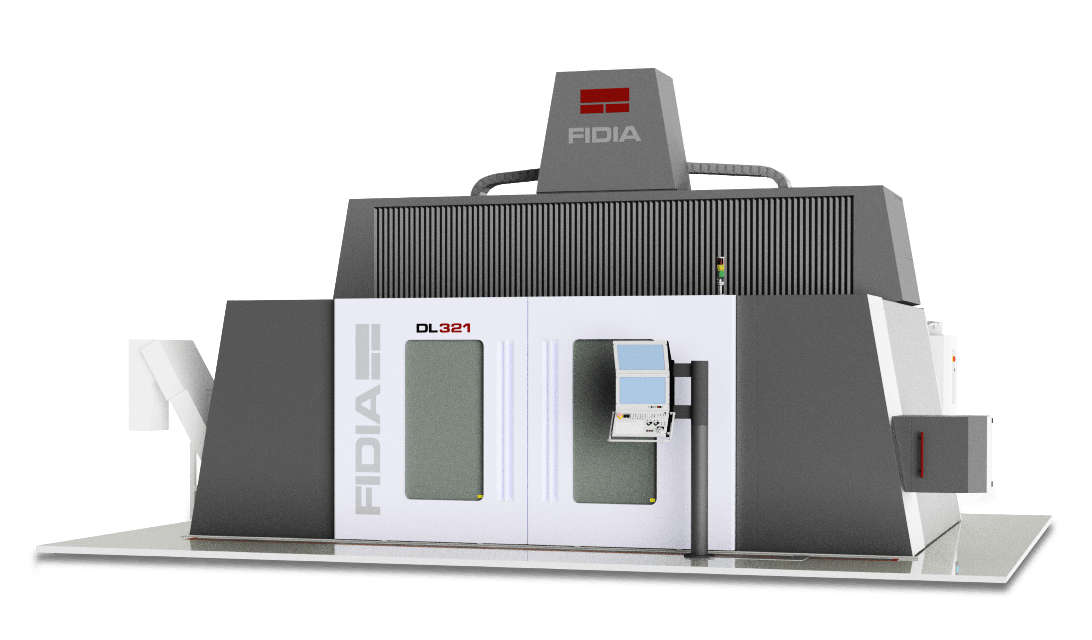

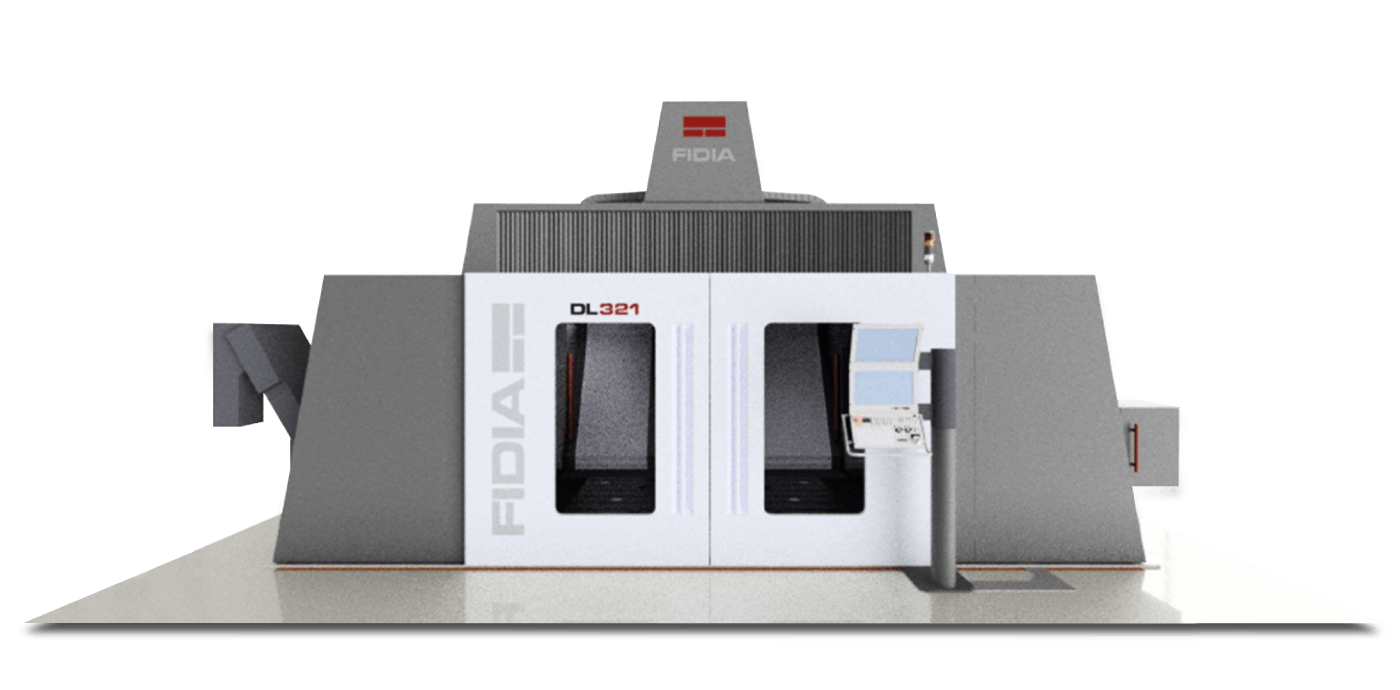

| D321 | Caratteristiche | ||

| Corsa asse X | 3000mm | ||

| Corsa asse Y | 2200mm | ||

| Corsa asse Z | 1100mm | ||

| Velocità assi | 24m/min | ||

| Dimensioni della tavola | 3000x2000mm | ||

| Portata della tavola | 3500 Kg/m² | ||

| Mandrini | M5A/55-24, M5A/55-20G M5A/65-15 |

||

Technical Specifications and Layout

| Axis Travels | Linea C3 | Linea C4 | Linea C6 |

| X (mm) | 2.200 (86") | 4.500 (177") | 6.200 (244") |

| Y (mm) | 3.000 (118") | 3.000 (118") | 3.000 (118") |

| Z (mm) | 1.200 (47") | 1.200 (47") | 1.200 (47") |

| X, Y, Z Speed axis (m/min) | 60/60/30 | ||

Dust extraction system

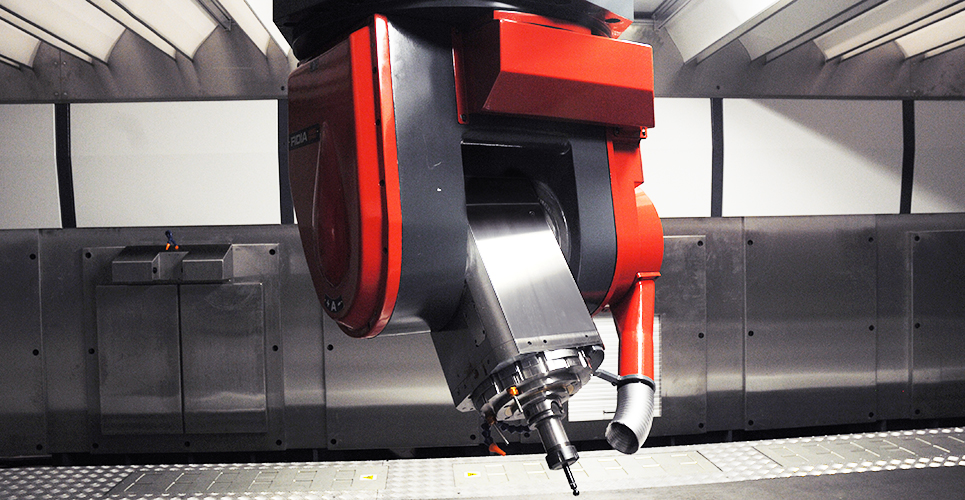

The Linea C integrates a modular and cutting-edge dust extraction system, specifically developed to face the challenges of machining critical materials such as composites, graphite, and ceramics. Our goal is to ensure maximum cleanliness, protecting both the operator and the machine's integrity.

The system offers precise dust capture directly at the source, thanks to flexible collectors (which follow the tool's movement) and innovative retractable hoods around the spindle. Among the most advanced solutions is the Programmable Suction model (DRP/M5-R2)*, which automatically adjusts the hood's position via CNC to adapt perfectly to the part's geometry, maximizing capture efficiency.

For safety, the Linea C is equipped with powerful ATEX Zone 22 Filtration Units, such as the DRS/ series, mandatory for potentially explosive dust (such as graphite and CFC). These units not only filter with high efficiency but also protect internal components with dedicated pressurization circuits. The extraction is completed by an effective push-pull airflow that keeps the entire working chamber clean, conveying the dust toward the high-capacity filters.

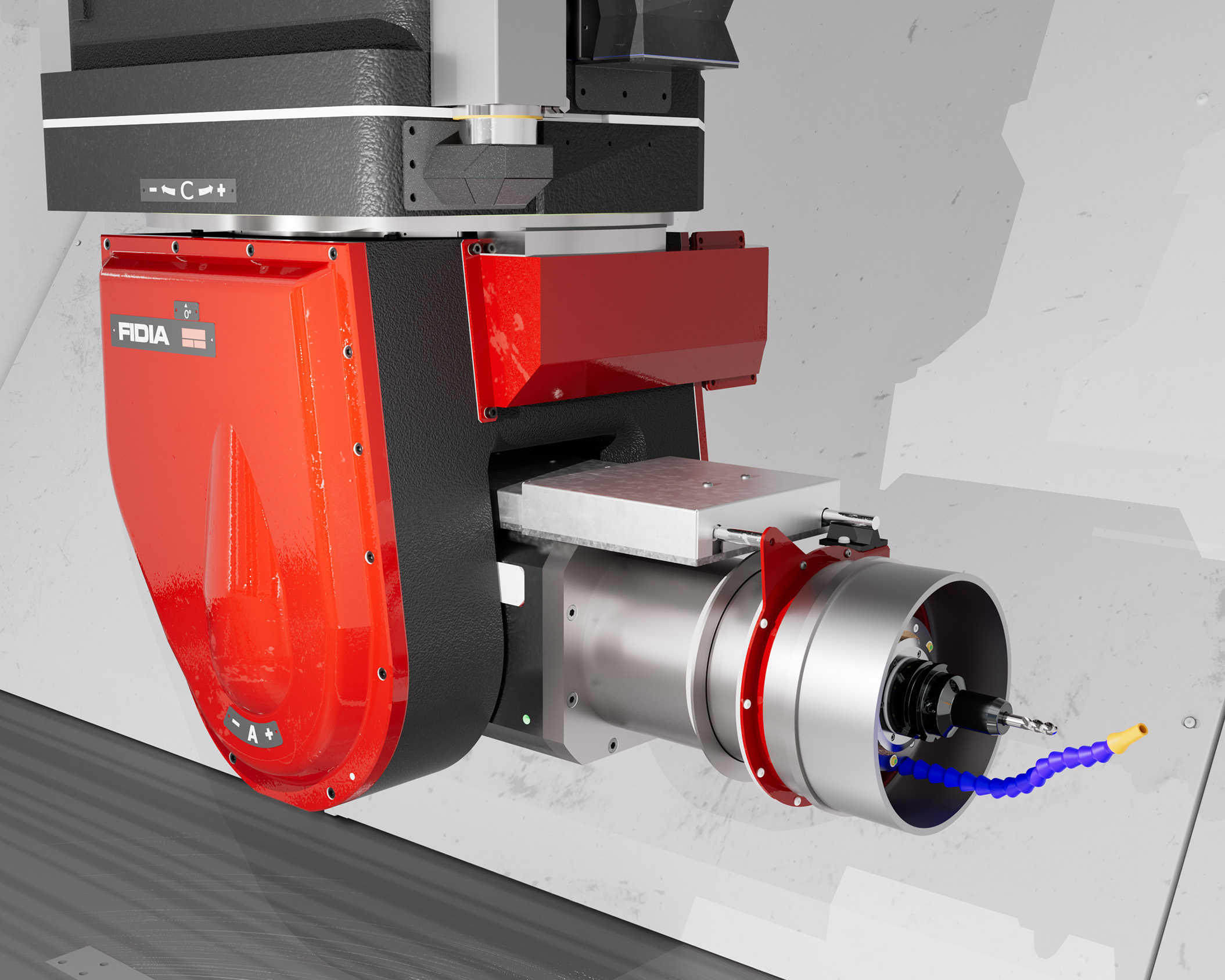

M5* - Continuous 5-axis heads

The M5A and M5C milling heads maximize performance in high-speed milling and cover a wide range of applications. With an asymmetrical design, they ensure dynamics, precision, and total control during machining, allowing for greater penetration in hard-to-reach areas.

- M5C are equipped with an aluminum body

- M5A are equipped with a cast iron body

Both heads can adopt various spindles, with permanent grease or air/oil lubrication:

| Spindle | Max. speed | Max. Power | Toolholder |

| 35-20G | 20.000 1/min | 35 kW | HSK63A |

| 35-24 | 24.000 1/min | 35 kW | HSK63A |

| 30L-20G | 20.000 1/min | 30 kW | HSK63A |

| 30L-24 | 24.000 1/min | 30 kW | HSK63A |

| Only for M5A | |||

| 55-20G | 20.000 1/min | 55 kW | HSK63A |

| 55-24 | 24.000 1/min | 55 kW | HSK63A |

Toll magazine

The milling machine is equipped with an automatic tool changer, featuring a 24 or 42-position magazine, an automatic protective door, and an external opening for tool loading and unloading. The TMS laser tool measurement system is positioned inside it.

Working area

The Flexible Clamping System with vacuum technology is a cutting-edge modular solution for the industry, designed to guarantee rapid retooling and positioning with absolute precision.