BRIDGE 4: Experience "Made in Italy" Excellence First-Hand

For a limited time, we are opening the doors of our Forlì manufacturing plant. We have just completed a BRIDGE 4 destined for a major European customer, a technological giant entirely designed, cast, and assembled in Italy.

This is not a simple showroom display, it is your chance to see the machine in its pre-shipment phase, observe the final testing procedures, and speak directly with the engineers who built it.

Book your visit

Contact your sales representative to schedule an appointment in Forlì.

OR

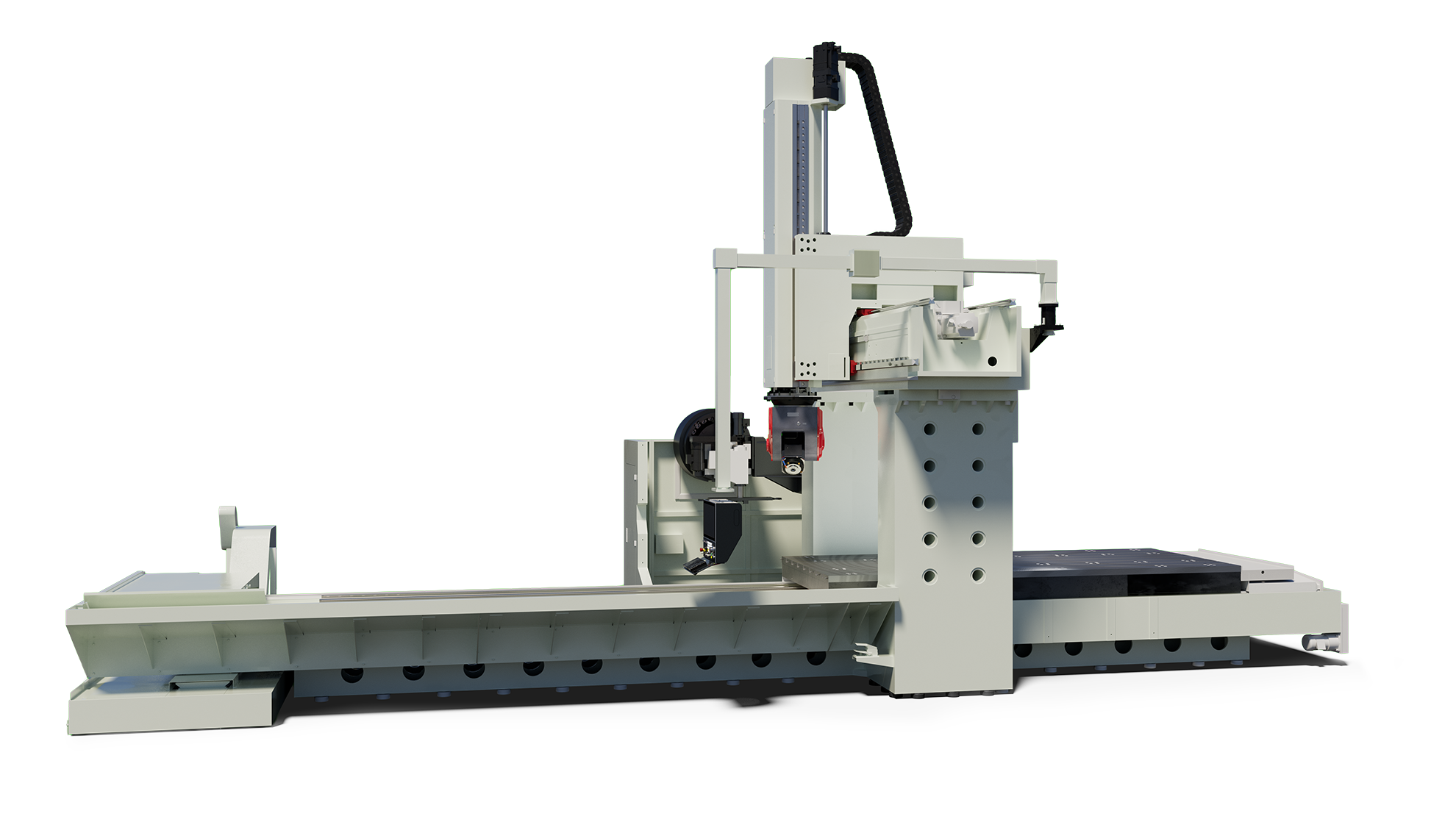

Robustness and stability for uncompromising machining

Engineered for the Toughest Challenges

Whether complex molds, automotive styling models, or aerospace structural components, the BRIDGE series delivers superior performance thanks to:

Uncompromising stability: The fixed gantry and moving table configuration ensures the part remains centered within the machine structure, ensuring flawless surface finishes even at high speeds. M5A 5-axis bi-rotary head designed to achieve complex undercuts and tight corners with extreme rigidity.

nC19-24 intelligence: The new Fidia CNC with ACL (Adaptive Control Logic) doesn't just execute a path, but actively optimizes the feed rate, reducing roughing times by up to 30%.

Complete accessibility: Large access doors and an ergonomic design make part setup and process monitoring simple, safe, and efficient.

Table and machining capacity

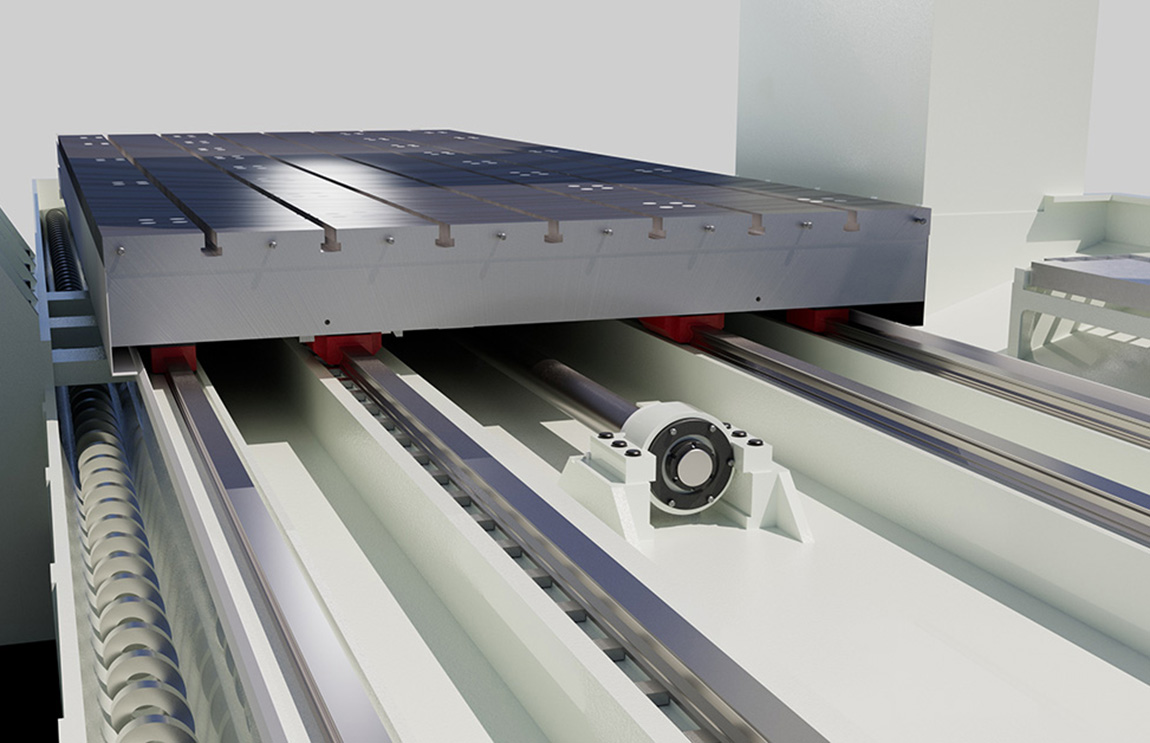

The moving table along the X-axis is equipped with T-slots for workpiece clamping.

Table movement is supported throughout the entire stroke, eliminating overhangs and deviations during machining.

Precision roller guides and the C3-class ballscrew, directly coupled to the axis brushless motor, guarantee high dynamics, precision, and repeatability.

The kinematics are protected by stainless steel covers, which shield the system from dust, chips, and coolant contamination, ensuring long life and operational reliability.