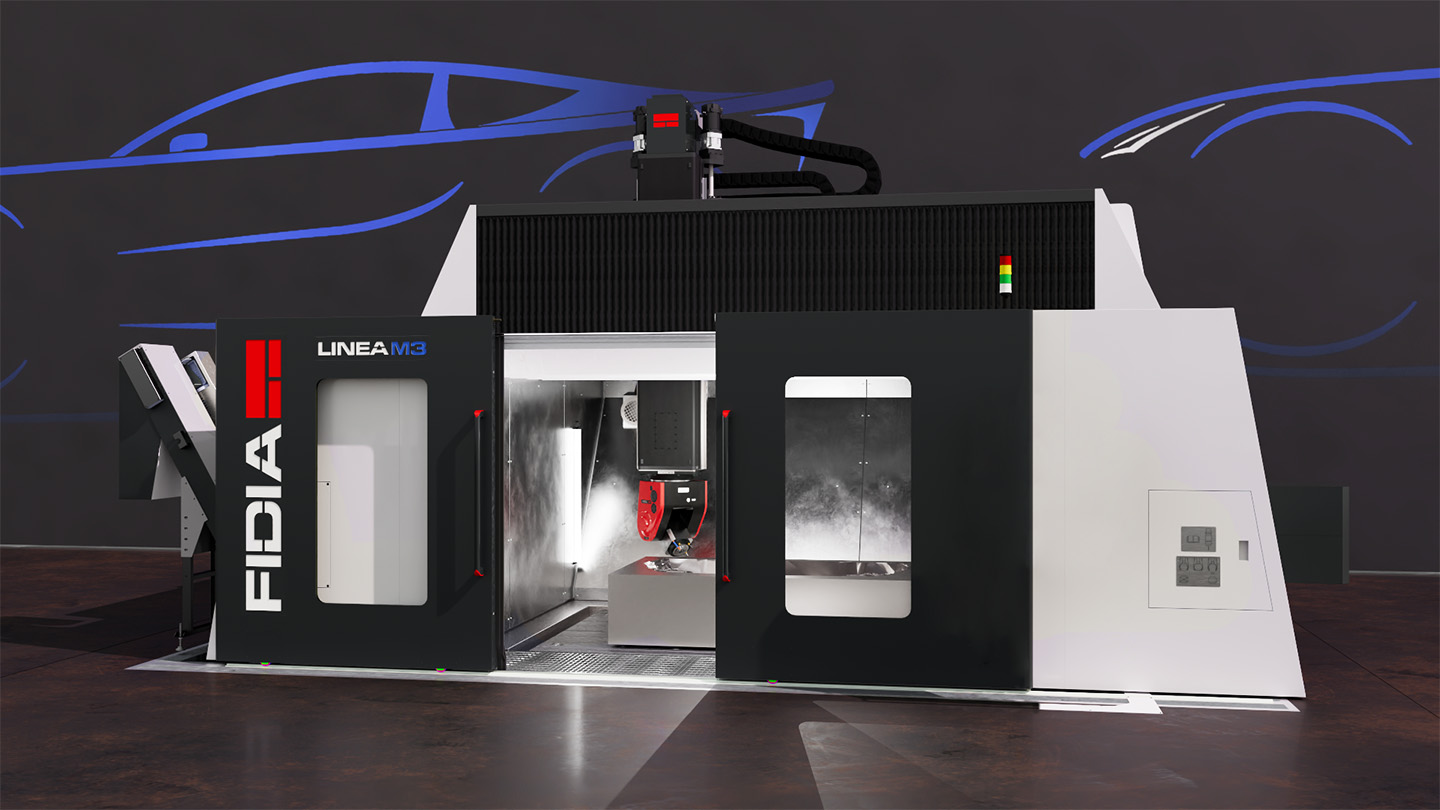

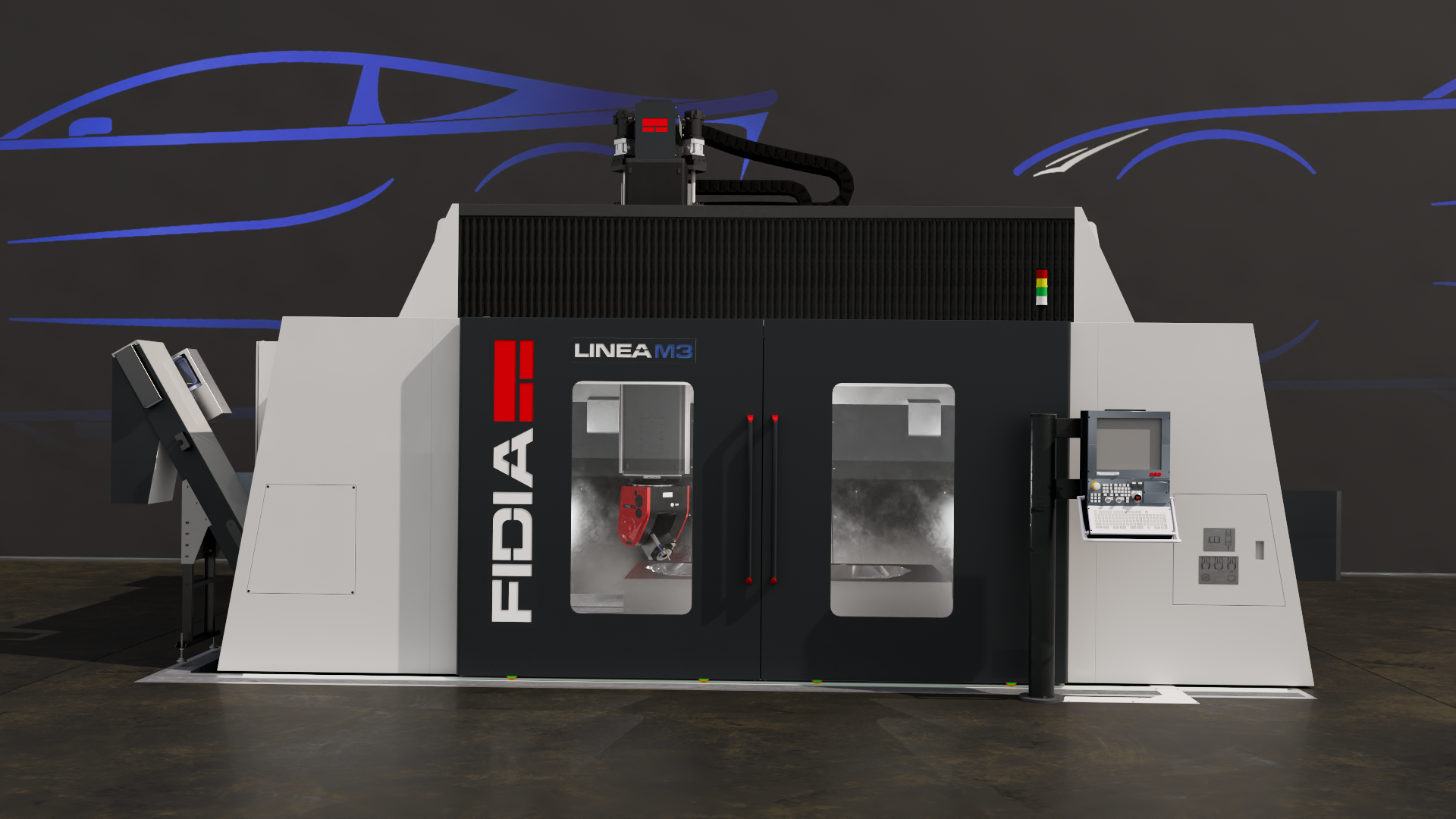

LINEA M

The compact Gantry for Molds and Tooling

Fidia presents “LINEA”, a new interpretation of a 5-axis machine with linear motors, characterized by dynamics and a winning quality-performance-price ratio. The modularity of the structural design allows for 3 sizes of X-axis travels, accompanied by a range of dedicated milling heads and accessories.

LINEA M is designed to perform complex machining typical of precision molds and tooling, offering a highly effective solution for semi-finishing and finishing operations. The more compact versions are ideal for mold sizes typical of plastic injection and die-casting, while the larger ones are well-suited for the sheet metal stamping field.

All machines comply with the European directives that allow access to Industry 5.0 tax incentives.

Specifiche tecniche e Layout

| D321 | Caratteristiche | ||

| Corsa asse X | 3000mm | ||

| Corsa asse Y | 2200mm | ||

| Corsa asse Z | 1100mm | ||

| Velocità assi | 24m/min | ||

| Dimensioni della tavola | 3000x2000mm | ||

| Portata della tavola | 3500 Kg/m² | ||

| Mandrini | M5A/55-24, M5A/55-20G M5A/65-15 |

||

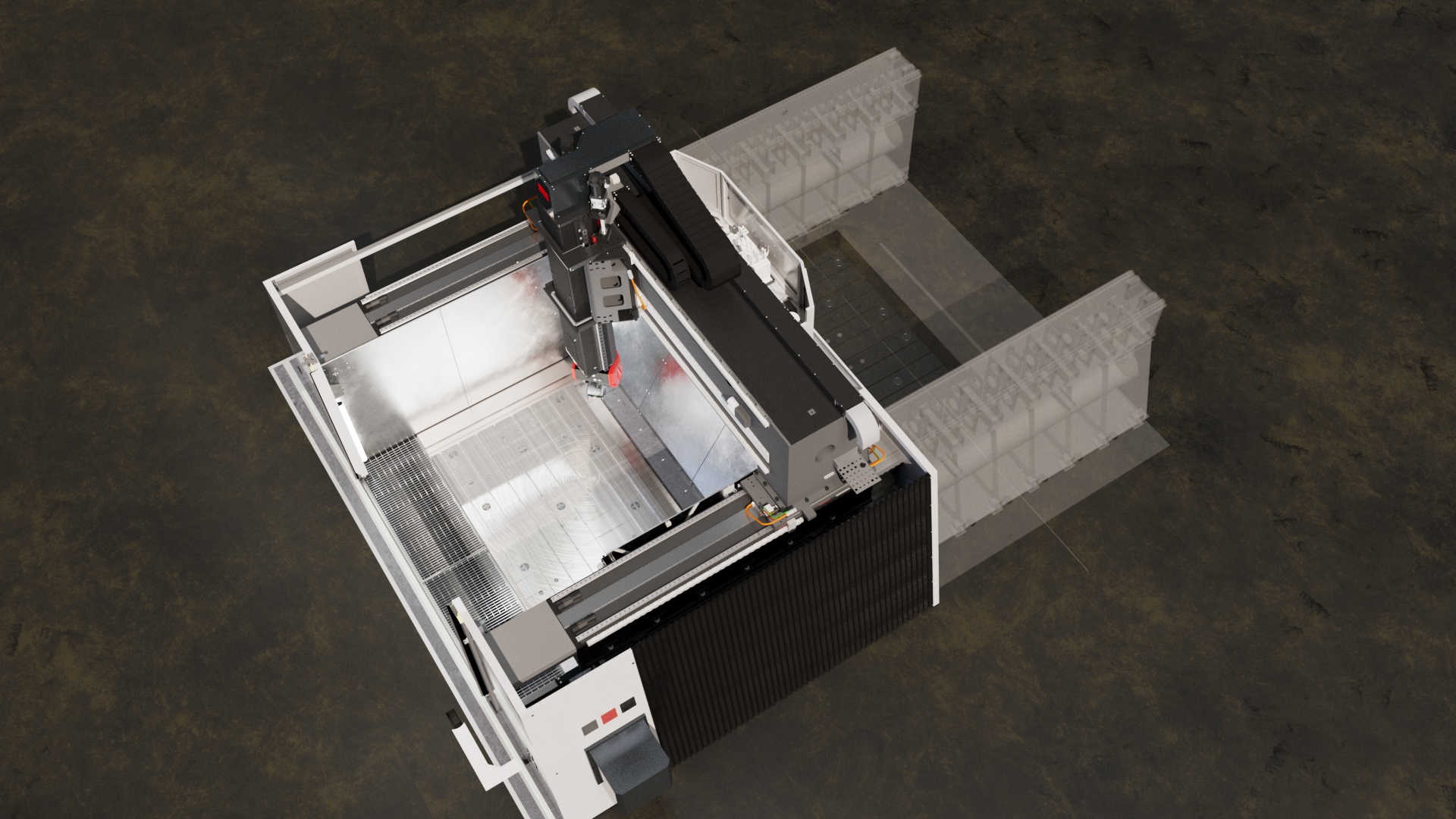

Technical Specifications and Layout

Fidia offers three versions of the LINEA M: M3, M4, M6

| Axis travel | Linea M3 | Linea M4 | Linea M6 |

| X (mm) | 2.200 (86") | 4.500 (177") | 6.200 (244") |

| Y (mm) | 3.000 (118") | 3.000 (118") | 3.000 (118") |

| Z (mm) | 1.250 (49") | 1.250 (49") | 1.250 (49") |

| X, Y, Z Axis speed (m/min) | 60/60/30 | ||

M5A milling head

The M5A milling head features a cast iron structure to guarantee robustness and thermal stability, and is particularly suitable for machining steel and cast iron as well as aluminum.

It is a continuous bi-rotary milling head ideal for performing the complete machining cycle, from roughing to finishing, specifically in high-speed machining that requires higher torque and power. Its compact structure allows access even into the narrowest cavities.

| M5A | Features | |||

| A axis travel | +95º ÷ -110º | |||

| C axis travel | C = ± 360º | |||

| Max. speed milling spindle | 24000 1/min or (20000 1/min)* | 20000 1/min | 15000 1/min or(12000 1/min)* | 12000 1/min |

| Max. power | 55 kW | 55 kW | 65 kW | 65 kW |

| Max.torque | 88 Nm | 124 Nm | ||

| Toolholder | HSK-A63 | HSK-A63 | HSK-A100 | HSK-A100 |

M5S: symmetrical bi-rotary head

The body of the M5S milling head is made of cast iron and its symmetrical fork structure optimizes thermal stability. The "tandem" dual-motor solution to control the A and C axes guarantees zero backlash and requires no maintenance. High-torque hydraulic brakes allow the axes to be locked in any position during high-material-removal machining.

| M5S | M5S/55-24 | M5S/65-15 | ||

| A axis travel | ±110º | |||

| C axis travel | ± 360º | |||

| Max. speed milling spindle | 24000 1/min or 20000 1/min* | 15000 1/min or 12000 1/min* |

||

| Max. power | 55 kW | 65 kW | ||

| Max. torque | 88 Nm | 124 Nm | ||

| Toolholder | HSK-A63 | HSK-A100 | ||