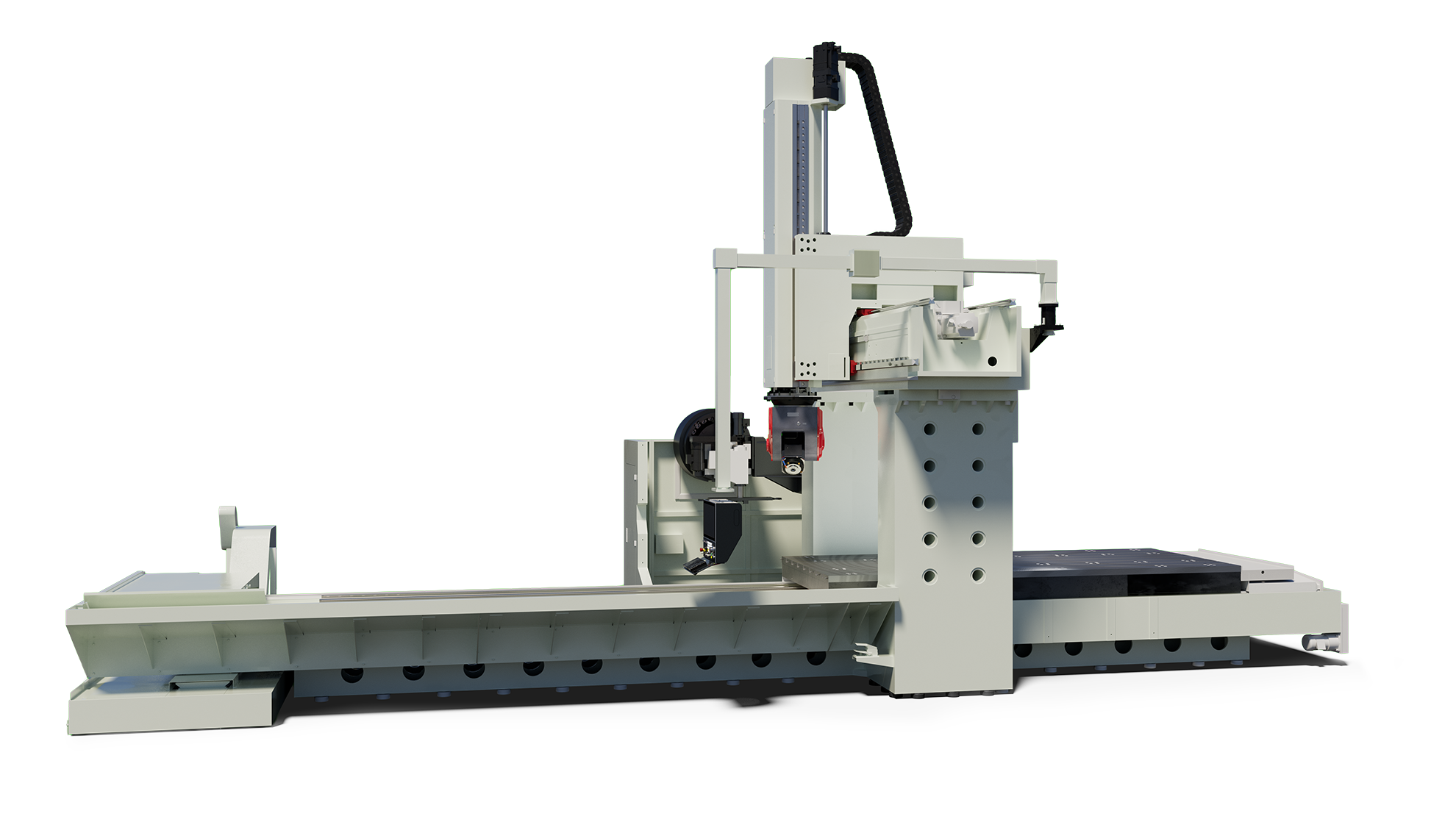

BRIDGE Milling Center

Fidia's BRIDGE is a 5-axis machine with a fixed portal structure and moving table. A solution that combines great robustness with excellent precision. The high-quality cast iron structures, optimized through FEM, ensure strength, allowing for high-speed roughing operations and, at the same time, finishing with high surface quality.

The wide space between the columns facilitates the assembly of equipment and complex parts, making BRIDGE extremely versatile. Thanks to the bi-rotary head and a selected range of accessories, integrated measurement systems, tool magazine with up to 60 positions, and a high-pressure cooling system, BRIDGE adapts to every production need, offering great flexibility in applications for molds, models, prototypes, and structural parts in the aeronautical sector.

Technical specifications

Three sizes

The BRIDGE series is available in three axis travel configurations and two spindle choices for the FIDIA 5-axis bi-rotary head.

| Axis travel | BRIDGE 2 | BRIDGE 3 | BRIDGE 4 |

| X (mm) | 2.200 (86") | 3.200 (126") | 4.200 (165") |

| Y (mm) | 1.750 (69") | 2.250 (88") | 2.250 (88") |

| Z (mm) | 1.000 (39") | 1.000 (39") | 1.000 (39") |

| Table | |||

| Dimension (XY) | 2.000 x 1.600 (79" x 63") | 3.000 x 1.600 (118" x 63") | 4.000 x x1.700 (157" x 67") |

| Max load (Kg) | 6.000 | 8.000 | 12.000 |

Structure

Robustness and stability for uncompromising machining

BRIDGE adopts a solid portal structure with a moving table, designed to guarantee maximum rigidity and precision even in the most demanding machining operations. The base is reinforced with dense ribbing and ensures excellent support for the workpiece table, guaranteeing resistance to high loads and cutting stresses.

Table and machining capacity

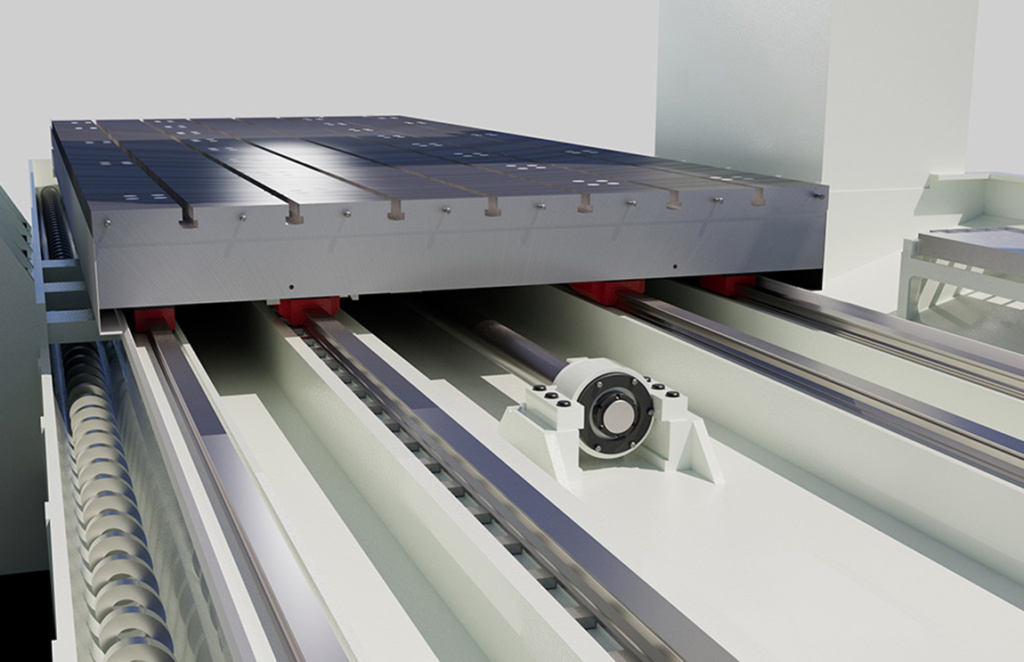

The moving table along the X-axis is equipped with T-slots for workpiece clamping.

Table movement is supported throughout the entire stroke, eliminating overhangs and deviations during machining.

Precision roller guides and the C3-class ballscrew, directly coupled to the axis brushless motor, guarantee high dynamics, precision, and repeatability.

The kinematics are protected by stainless steel covers, which shield the system from dust, chips, and coolant contamination, ensuring long life and operational reliability.

Y, Z: stability and precision

The Y-axis consists of a carriage supported by 3 roller guides positioned on two sides of the robust crossbeam, promoting perfect orthogonality of the sliding planes.

The Y-axis consists of a carriage supported by 3 roller guides positioned on two sides of the robust crossbeam, promoting perfect orthogonality of the sliding planes.

RAM

A fundamental role is entrusted to the vertical RAM, characterized by a generous section, driven by two ballscrews with brushless motors in tandem. This configuration allows deformations to be minimized and ensures consistently precise machining.

M5A Bi-rotary Head

M5A Bi-rotary Head

The M5A head maximizes performance in high-speed milling across various applications.

Its compact and asymmetrical structure facilitates machining in areas that are most difficult to access.

The M5A head features a cast iron structure to guarantee robustness and thermal stability, and is particularly suitable for machining steel and cast iron as well as aluminum.